O-Ring NSF

Get a Quote

O-Ring NSF Certified

GMORS offers o-rings and seals for drinking water applications with

compliance to WRAS Standards and NSF 61 (National Sanitation Foundation).

Our R&D team of engineers formulate at least 20 compounds suitable for

drinking water applications complying with the above standards.

NSF Standards 61: The guidelines which regulate the requirements of

system components and chemicals that is exposed to drinking water during

treatment is NSF Standards 61. The standards ensure that chemicals and

substances that are toxic do not end up in drinking water systems, causing

adverse effects on health.

WRAS: Water Regulations Advisory Scheme

The approval scheme in the United Kingdom that regulates the use of

components and materials to ensure non-contamination of water supply system

sis the WRAS.

Background

For many years, the potable water industry makes use of chlorine as a

disinfectant against bacteria. However, the use of chlorine in drinking

water systems gives rise to DBP (disinfectant-by-products) which at higher

concentration, has been shown to be carcinogenic. The EPA (Environment

Protection Agency) set limits on the level of disinfectant-by-product to be

found in potable drinking systems.

The new regulatory limits set by the Environment Protection Agency resulted

in chloramine been used as a substitute for chlorine as municipalities,

water processing and distribution facilities find ways to reduce

disinfectant-by-products caused by chlorine usage. Although chloramine

produces less DBP, it has a damaging effect on elastomeric seals, giving

rise to a loss of resilience and excessive swelling. A higher incidence of

failure of elastomeric seals and gaskets occurs with the use of chloramine

as disinfectant, with sulfur-cured elastomers performing less satisfactory

than peroxide-cured elastomers. It has been tested and shown that chloramine

has a more damaging effect on certain elastomers.

GMORS Solution: Chloramine-Resistant Elastomers

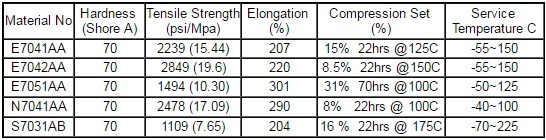

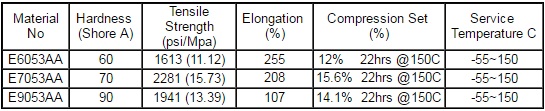

Sealing systems formulated to be chloramine resistant are offered by GMORS,

with a selection of elastomeric compounds available.

Ethylene propylene diene monomer (EPDM) has excellent resistance to

chlorine found in drinking water, and is extensively used in drinking water

systems. At higher concentrations of chlorine or chloramine however,

additional resistance testing is necessary. Formulation-resistant

formulations of EPDM has a higher level of saturated ethylene and a lower

level of carbon black.

Silicone (VMQ) performs better against chloramine attack as compared

to other elastomers. However, silicone has a lower abrasion resistance and

lower tensile and tear strength. The lesser mechanical properties of

silicone has to be taken into account while considering the benefits of its

resistance to chloramine attack.

Contact us for a cost efficient recommendation of a chloramine-resistant

sealing system.

Copyright © 2017 Ge Mao Rubber Industrial Co., Ltd.